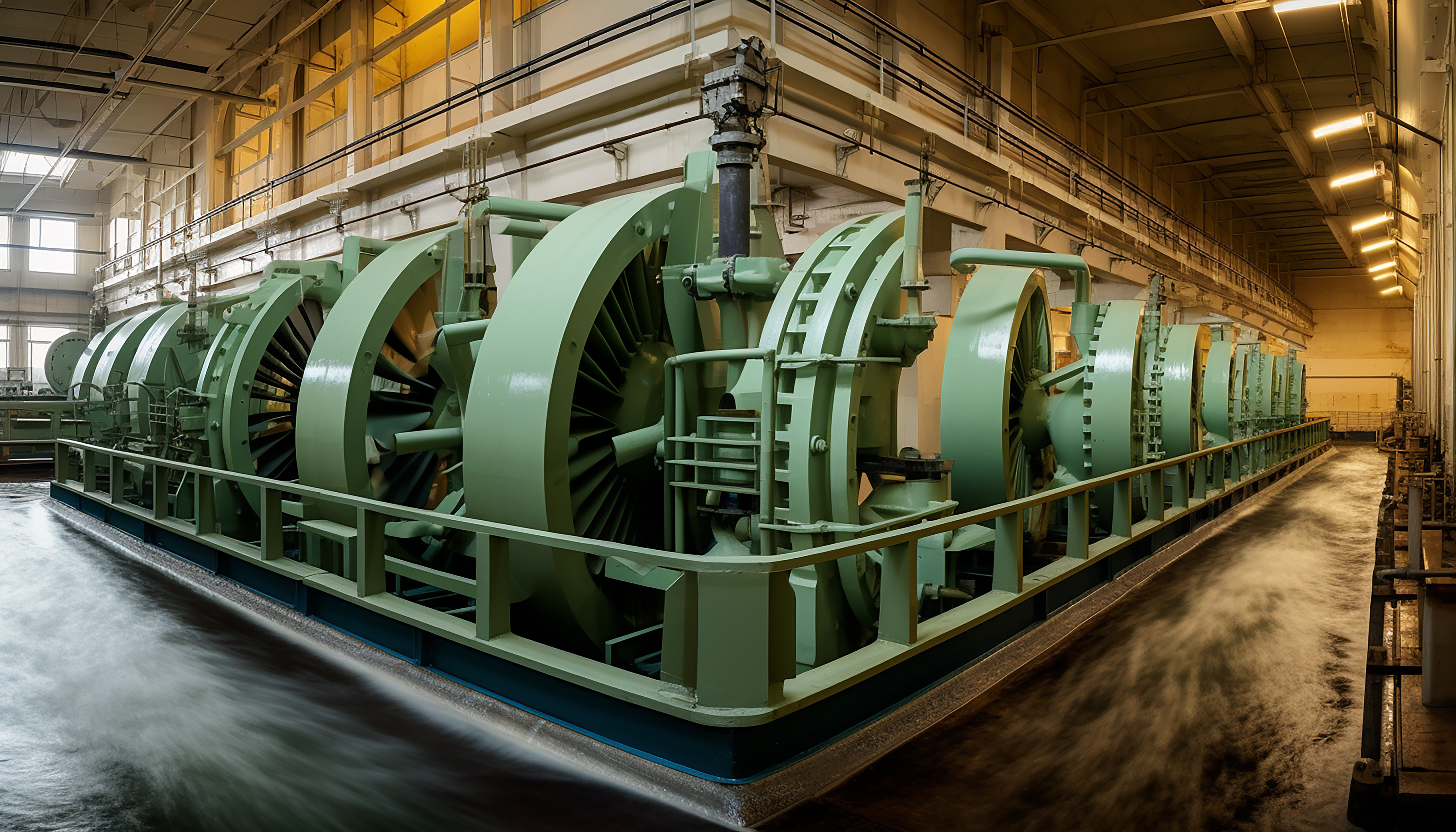

Chiller Plant

SVG’s chiller plants play a vital role in removing heat from liquids. The cooled liquid can then be circulated through a heat exchanger to cool equipment. Industrial water chillers are widely used across various applications where chilled water or fluid is essential.

These systems are commonly utilized to cool products and machinery in industries such as injection molding, tool and die cutting, food and beverage production, chemicals, lasers, machine tools, semiconductors, and more.

Air Cooled Chiller

SVG’s air-cooled chillers efficiently absorb heat from process water and release it into the surrounding air. These units are ideal for environments where the discharged heat is not a concern and can even be advantageous, such as providing warmth during colder months.

Air-cooled chillers are commonly installed in mechanical equipment rooms or near the areas they are designed to cool, ensuring optimal performance and convenience.

Water Cooled Chiller

SVG’s water-cooled chillers are versatile solutions used across various applications where chilled water or liquids are circulated through process equipment. These chillers are widely employed to cool products and machinery in industries such as injection molding, tool and die cutting, food and beverage, chemicals, lasers, machine tools, semiconductors, and more.

The primary role of an industrial chiller is to transfer heat from one source, typically process equipment or products, to another, often the external air outside the manufacturing facility, ensuring optimal cooling efficiency.

Skid Mounted Chiller

SVG’s skid mounts provide an efficient and

reliable method for distributing and storing industrial machinery.

In simple terms, the

equipment is permanently installed within a sturdy frame, on rails, or on a metal pallet

at the point of manufacture. This design allows the machinery to be safely and

conveniently transported and operated

as a single, cohesive unit.

Green Cooling Chillers

SVG’s Green Chillers utilize eco-friendly natural refrigerants like CO₂, ammonia, hydrocarbons, air, and water, unlike artificial refrigerants such as CFCs, HCFCs, and HFCs. These natural refrigerants have zero ozone depletion potential and minimal to no global warming potential, making them a sustainable choice.

While natural refrigerants require additional safety precautions due to their unique properties—such as flammability in hydrocarbons and ammonia's flammability, corrosiveness, and higher toxicity—these challenges can be effectively managed. Proper material selection, the use of secure components, and comprehensive technician training ensure the safe and efficient operation of SVG’s Green Chillers.

Modular Chiller

SVG’s modular chillers are engineered with separate electrical feeds, providing inherent redundancy that traditional single-power-source chillers lack. This means that if one module requires servicing or experiences a failure, the remaining modules can continue operating seamlessly, ensuring your building maintains full functionality without interruptions.

SVG’s modular chillers offer versatile capabilities, including heating, cooling, heat recovery, and heat pump technology—all within each module. They can also utilize both air and water to deliver simultaneous heating and cooling, eliminating the need for geothermal systems.

The chiller plant operates efficiently based on a proper refrigerant cycle, leveraging vapor compression or absorption techniques to cool the fluid, enabling precise heat transfer for optimal performance. Whether it’s compression or absorption, SVG ensures reliability and efficiency in every system.

Frequently asked questions

A chiller plant is a system designed to remove heat from a building or industrial process by circulating chilled water. It operates using either vapor compression or absorption technology to cool water, which is then used to regulate indoor temperatures or maintain process cooling.

SVG provides a wide range of chiller plants, including air-cooled and water-cooled systems. Our solutions cater to various applications, such as HVAC systems, industrial processes, and commercial buildings, ensuring energy-efficient and reliable performance.

Selecting the right chiller plant depends on factors such as the cooling load, facility size, operational requirements, and energy efficiency goals. SVG’s experts conduct a detailed assessment to recommend the ideal system tailored to your specific requirements.

Modular chiller plants offer flexibility, energy efficiency, and scalability. They feature separate modules with independent power feeds, allowing for redundancy. If one module requires maintenance, the others can continue operating, ensuring uninterrupted cooling.

Yes, SVG offers comprehensive maintenance services, including regular inspections, performance optimization, and emergency repairs, ensuring your chiller plant operates efficiently and reliably over its lifespan.